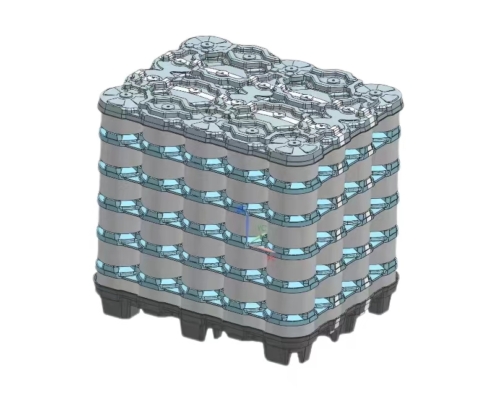

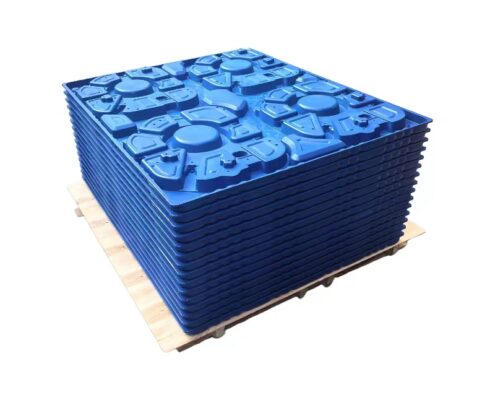

Vacuum Forming Plastic Tray

SME Plastic is your trusted supplier for custom vacuum forming plastic trays from China. We offer a wide range of materials, styles, and customization options to meet your specific needs. From protective packaging to retail displays, our high-quality trays are designed to impress. Durable, versatile, and cost-effective solutions for any industry. Contact us to get customized quote today!

Benefits of Vacuum Forming Plastic Trays

Cost-Effectiveness: Vacuum forming allows for lower production costs compared to other molding methods, making it a budget-friendly choice for both small and large batch productions.

Versatility: It can accommodate a wide variety of designs, sizes, and thicknesses, offering solutions tailored to specific needs.

Speed to Market: This method boasts shorter lead times, ensuring your product reaches the market faster.

Quality and Durability: High-quality materials are used to ensure the trays are durable, able to withstand various conditions.

Customization: Offers immense flexibility in terms of customization, enabling the creation of trays that perfectly fit your product’s specific dimensions and requirements.

FAQs

Which materials are best for vacuum forming plastic trays?

The choice of material for vacuum forming plastic trays depends on the application’s specific requirements, including durability, clarity, chemical resistance, and recyclability. Common materials include Acrylonitrile Butadiene Styrene (ABS), Polystyrene (PS), Polyethylene Terephthalate (PET), and High Impact Polystyrene (HIPS).

- ABS offers strength and thermal stability.

- PET is preferred for clarity and recyclability.

- HIPS is used for its impact resistance.

What are the design considerations for vacuum forming plastic trays?

When designing vacuum-formed plastic trays, several key factors must be considered to ensure functionality and manufacturability. These include the draft angles (to facilitate removal from the mold), wall thickness uniformity (to prevent warping or weak spots), and the inclusion of features like ribs or gussets to enhance strength and rigidity.

- Draft angles facilitate mold removal.

- Uniform wall thickness prevents defects.

- Ribs or gussets can be added for strength.

What industries use vacuum formed plastic trays?

Many industries use our trays, including electronics, food packaging, cosmetics, pharmaceuticals, and automotive. We even create custom trays for retail displays and industrial applications.

What are the different types of vacuum formed plastic trays you offer?

We offer a wide range of tray styles including:

Blister packs

Clamshells

Flocked trays

Insert trays

Shipping trays

Component trays

Can you create custom vacuum formed plastic trays?

Absolutely! We specialize in creating custom trays to fit your specific needs. Just provide us with your design specifications or a sample, and we will bring your vision to life.

Can you add logos or branding to the trays?

Yes, we can incorporate logos, text, and other branding elements into the design of your custom trays using embossing, debossing, or printing techniques.

How long does it take to get custom vacuum formed trays?

Production time depends on the size and complexity of your order. We’ll provide you with an estimated timeframe after discussing your project requirements.

Do you offer design assistance for custom trays?

Yes, we have a team of experienced designers who can help you create the perfect tray for your needs. We’ll work closely with you to ensure the design meets your specifications and functions flawlessly.

Are your plastic trays food safe?

We offer food-grade plastic materials that comply with safety regulations for direct food contact.

What are the available colours for the plastic trays?

We offer a wide range of standard colours and can also match custom colours to meet your branding requirements.

What are the thicknesses available for the plastic trays?

The thickness of the plastic sheet depends on the desired rigidity and application of the tray. We offer vacuum formed plastic trays with thicknesses among 0.2-12 mm to suit your specific needs.

Do you offer any eco-friendly options for plastic trays?

Yes, we offer trays made from recycled materials and biodegradable plastics. We are committed to sustainable practices and can help you find the best eco-friendly solution.

Do you provide samples?

Yes, we can provide samples of existing trays or create prototypes of your custom design upon request.