Vacuum Forming Thick Plastic

SME Plastic is a professional supplier specializes in manufacturing thick gauge & heavy gauge plastic vacuum forming products, offering a wide range of materials and capabilities to meet your exact needs. From design assistance to final production and finishing, we’re here to bring your ideas to life. Contact us today to discuss your project and discover the possibilities of thick gauge plastic vacuum forming with SME Plastic!

Thick Gauge vs. Heavy Gauge Vacuum Forming, What are the Difference

While the terms “thick gauge” and “heavy gauge” might seem interchangeable in the context of vacuum forming, there’s a subtle distinction between the two:

Thick Gauge Vacuum Forming

Generally refers to plastic sheets with a thickness of 3mm and above. This is a broad category encompassing a wide range of thicknesses and applications.

Focuses on the inherent strength and durability that comes with using thicker materials.

Suitable for a variety of projects including trays, enclosures, machine covers, automotive parts, and more.

Heavy Gauge Vacuum Forming

Typically refers to the upper end of the thickness spectrum within thick gauge vacuum forming. This might involve sheets with thicknesses exceeding 6mm or even reaching 10mm or more.

Emphasizes the significant weight and robustness of the formed parts.

Often used for demanding applications requiring exceptional strength, rigidity, and impact resistance, such as large industrial equipment housings, construction components, or heavy-duty containers.

In essence, “heavy gauge” can be considered a subcategory within “thick gauge” vacuum forming, specifically highlighting the use of exceptionally thick and heavy materials for particularly demanding applications.

Here’s a table summarizing the key differences:

| Feature | Thick Gauge | Heavy Gauge |

| Thickness Range | 3mm and above | Typically 6mm and above (upper range of thick gauge) |

| Emphasis | Strength and durability | Significant weight and robustness |

| Typical Applications | Wide range including trays, enclosures, machine parts | Demanding applications needing exceptional strength and rigidity (e.g., industrial equipment, construction) |

FAQs

What is vacuum forming thick gauge plastic?

Vacuum forming thick gauge plastic is a manufacturing process where we heat a thick plastic sheet (typically 3mm or more) and then use vacuum pressure to mold it over a custom-designed form. This allows us to create strong, durable, and three-dimensional parts with a wide range of applications.

What are the processes of vacuum forming thick gauge plastic?

Material Selection: We start by choosing the right type of thick plastic sheet based on your project’s needs. Popular choices include ABS, HIPS, HDPE, and PP, each with unique properties like impact resistance, flexibility, and chemical resistance.

Heating the Sheet: The chosen plastic sheet is heated until it becomes soft and pliable, but not molten.

Vacuum Forming: The heated sheet is placed over the mold, and a vacuum is applied, sucking the sheet tightly against the mold’s contours. This creates a precise replica of the mold’s shape.

Cooling and Release: The formed plastic is allowed to cool and solidify, maintaining the shape of the mold. It is then released, resulting in the final 3D part.

Finishing Touches: Depending on your needs, we can apply various finishing techniques like trimming, drilling, CNC machining, or printing to complete the part.

What are the advantages of vacuum forming thick gauge plastic?

Strength and Durability: Thick gauge plastic offers excellent impact resistance and can withstand heavy use or harsh environments.

Design Flexibility: This process allows for creating complex shapes and intricate details with high precision.

Cost-Effectiveness: Compared to other manufacturing methods for similar parts, vacuum forming is often more economical, especially for medium to large production runs.

Versatility: Thick gauge vacuum forming is suitable for a wide range of applications, from industrial equipment housings to medical device components and consumer products.

What kind of products can be made with thick plastic vacuum forming?

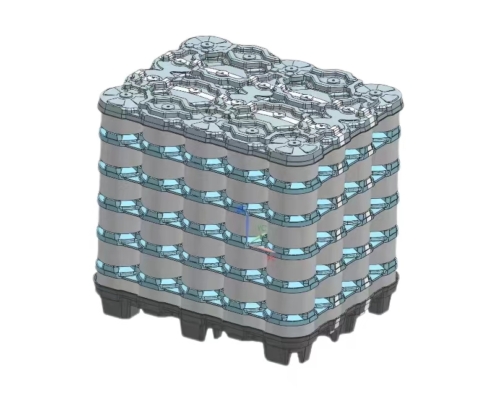

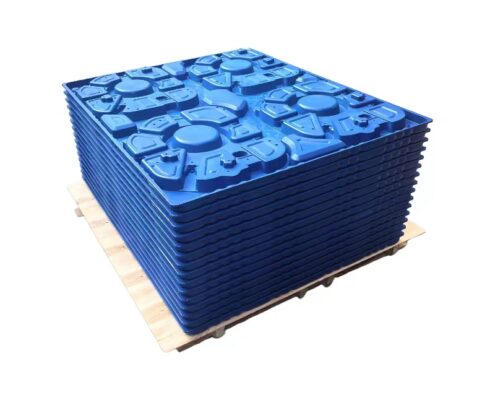

Trays and Containers: Used in various industries for material handling, storage, and organization.

Enclosures and Housings: Protecting sensitive equipment and electronics.

Machine Covers and Guards: Providing safety and protection for machinery.

Automotive Components: Creating durable interior and exterior parts.

Medical Device Components: Manufacturing trays, covers, and housings for medical equipment.

Prototyping: Creating prototypes for testing and design verification before mass production.

How thick is "thick plastic" when it comes to vacuum forming?

Usually, when we talk about thick plastic vacuum forming, we’re working with sheets that are over 3mm thick. But don’t worry, we can handle even thicker plastic upto 12mm depending on your needs!

What types of thick gauge plastic do you use for vacuum forming?

We offer a variety of thick plastic materials for vacuum forming, including ABS, HIPS, HDPE, PP, and more. Each material has its own unique properties, so we can help you choose the right one for your project.

Can you create custom colors and textures for thick plastic parts?

Yes, we can! We offer a wide range of color and texture options to match your specific requirements and branding needs.

Do you offer finishing services for thick plastic parts?

Yes, we offer a variety of finishing services, including trimming, drilling, CNC machining, and printing, to ensure your parts are ready to use.